Who is hara?

We? Although I came up with the idea for the bike, it is not mine;

the project was largely implemented by me, but would never have been possible without the support of those around me. That’s why I couldn’t bring myself to write these texts in the first person.

I am Remy. I’ve been working as a bike courier for over 12 years, mostly full-time. Cargo bikes are the best means of transportation: because the car is not an alternative. Cargobikes don’t make any noise or exhaust fumes, but they are fun. They take up little space, support short distances and small circuits… Cargo bikes are simply good. But they could be better. Anyone who rides a cargo bike a lot also knows their weak points. I’ve had more than enough time on the road to think about what could be improved.

I have been working on hara for four years. The decision to produce it myself was born out of necessity, as there are hardly any frame construction companies left in Europe that are capable of doing so.

My life revolves around bicycles. I worked in an ambitious courier cooperative in various roles, I was active in the courier culture and in my spare time I play bicycle polo. In 2022, I won the cargo bike race at the German Courier Championships with the first Hara prototype.

And about the name: hara is Japanese and means belly, whereby in Japanese one speaks “from the belly” and not from the heart, etc. So that’s where the soul resides, and somehow I like that idea.

So trust your hara!

Environment…

As a political person, I find it difficult to understand apolitical people. The fact that it should be possible to be an apolitical cargo bike manufacturer is even harder for me to understand.

Nevertheless, there is not a word about ecology, climate, production conditions in the Far East (where the messenger cargo bikes all come from), corporate democracy or anything else on the “About” pages of the competition.

This is both shocking and to be expected. After all, we wouldn’t have been able to get money from any bank with this business plan: selling technically more complex bikes, made in Germany and equipped to a higher standard at the same price can’t work. Unless, of course, you do it for the idea and not for the money.

…and production

During the development of this bike, we ordered a lot of stuff, produced a lot of waste and put our energy into it when we could have used it elsewhere. Whether this makes sense in the end, because the concept will prevail, depends on you.

Around three quarters of the tubes for hara are cold-drawn near Milan. Unfortunately, most of the steel for this still comes from China – although it is not unlikely that China will decarbonize its steel industry faster than us, which of course won’t change the transport and working conditions.

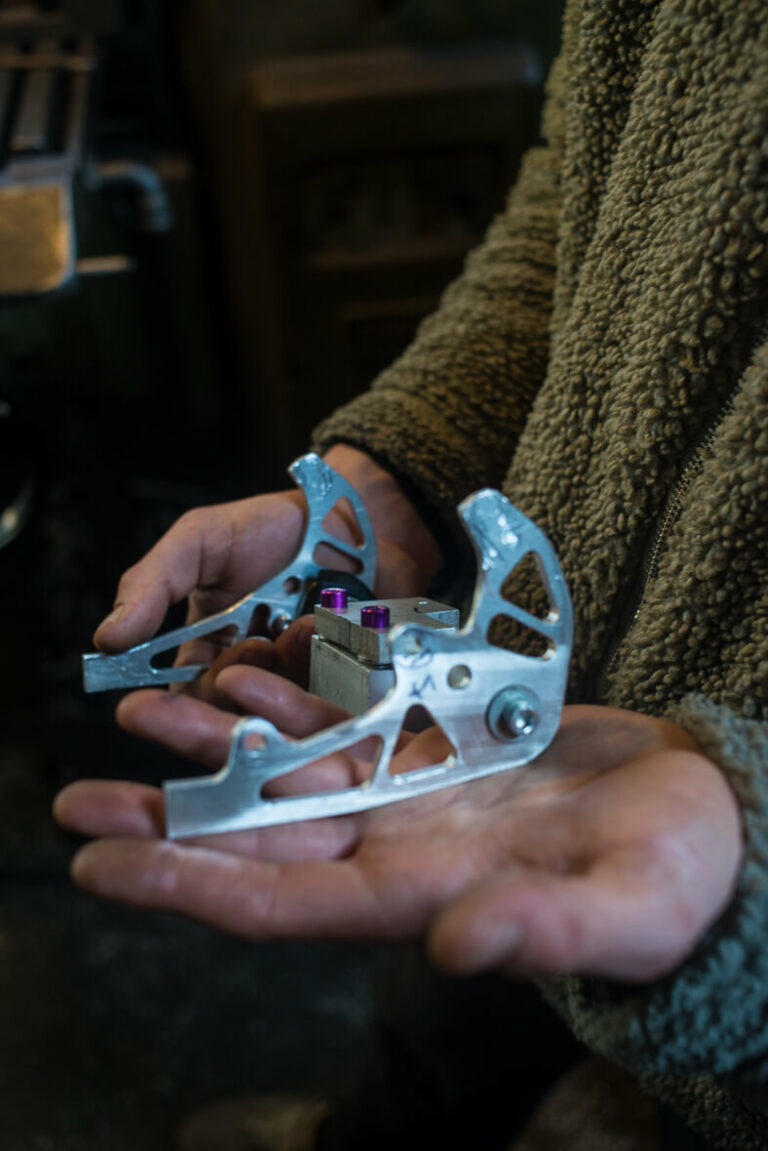

All machining and production orders for small parts were placed in Europe, and mostly locally.

The cargo boards are made of recycled plastic and are manufactured in Germany. For the components, we are for now relying on a mix of new and second-hand parts.

This first series is manufactured in Kollnau, BW, in a workshop that has lain idle for many years and on old machines.

And finally, at hara the one who came up with the idea is the same person that has to pull it through. Externalizing the costs in the form of low-wage labour, environmental consequences etc. to the other side of the world only encourages us Westerners to implement our “innovations” – I, on the other hand, will be careful next time.

By the way, on the subject of the global division of labor, it’s worth reading up on the 9-9-6 system.

Talking about it or joining

If you like hara – tell others. And tell me about it. I am looking forward to hearing from you. And anyone who wants to take part is even more welcome!